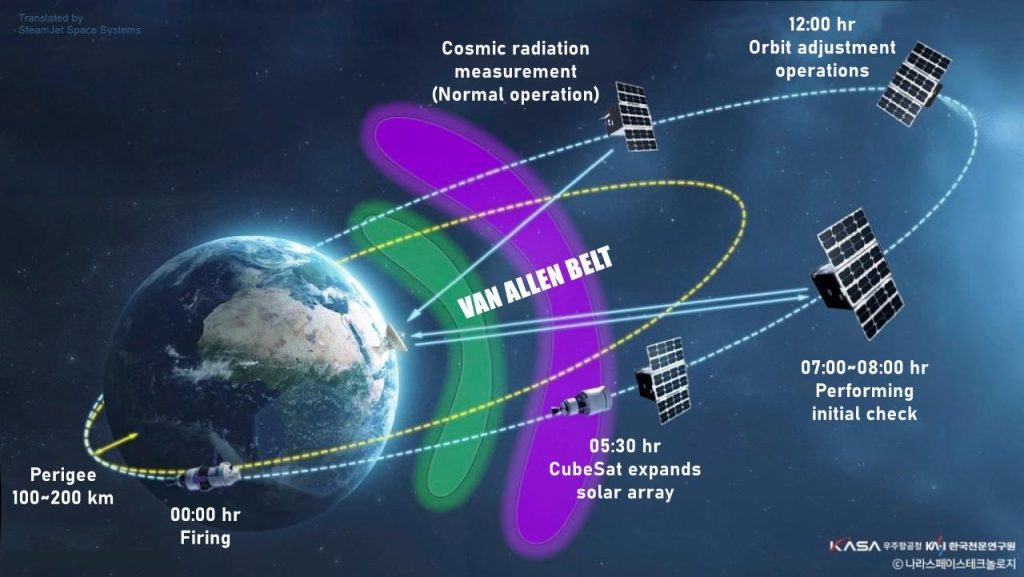

SteamJet Thruster One will perform an orbit correction for South Korea’s K-Rad Cube satellite during the upcoming Artemis II mission. South Korean NaraSpace designed and built the K-Rad Cube satellite for NASA’s historic Artemis II mission, the first crewed lunar mission in over 50 years.

Once deployed into a highly elliptical orbit, the satellite will face an immediate challenge because its first perigee passes through Earth’s upper atmosphere. SteamJet Thruster One will provide the orbital correction required to prevent the satellite’s re-entry into the atmosphere.

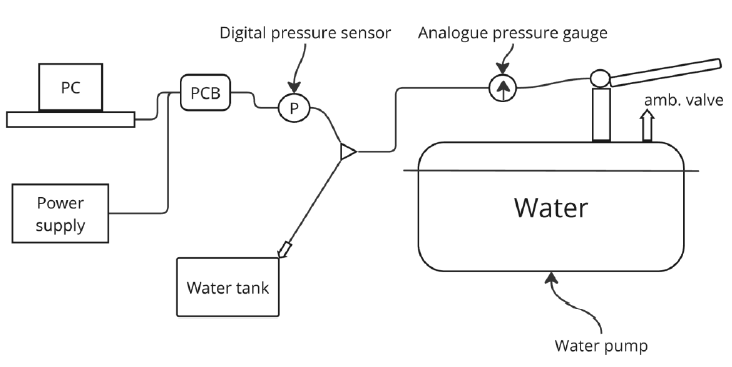

Before any mission, SteamJet thrusters undergo a meticulous testing process to guarantee performance and reliability. Fuel tank burst pressure testing was also completed to meet the elevated safety standards required for the crewed Artemis II mission.

In addition to burst testing, engineers conducted acceptance testing on the SteamJet Thruster One for Artemis II, following established industry practices. Acceptance test campaign consists of several phases:

- Functional test

- Vibration dynamic test

- Thermal vacuum test

- Leak rate

Functional test

Functional testing verifies the thruster’s performance in all operational modes. The flight profile details all settings relevant for in-orbit operation aboard the satellite. For the Artemis II mission there are two main operational modes: commissioning and thrust.

The commissioning mode is the first operational state activated post-launch. It purges residual gases from the fuel lines.

For the Artemis II mission the thruster was optimized to deliver high thrust, operating nearly in continuous mode. This configuration ensures the mission objective is met, raising the orbit perigee to over 180 km during the first orbit.

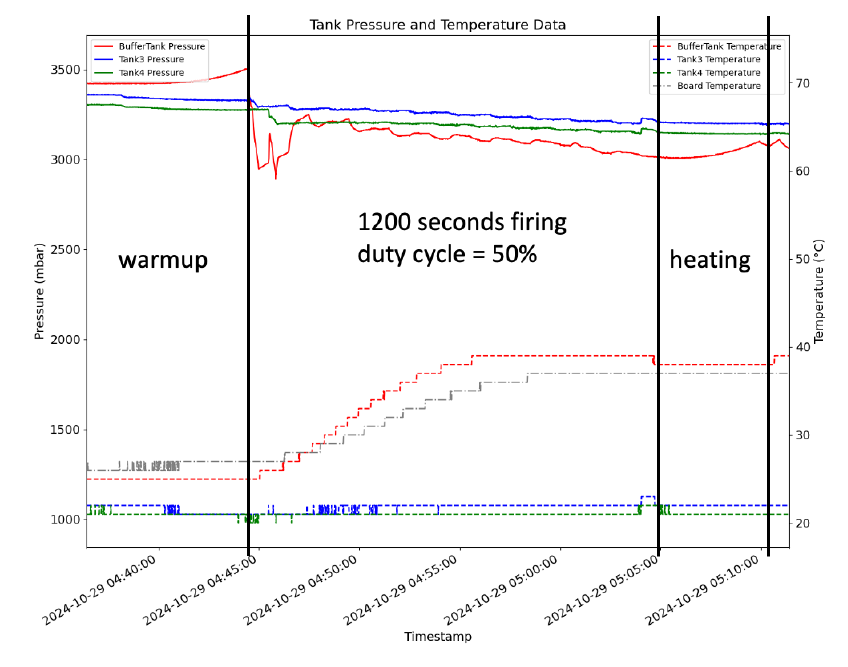

An impulse of 240 Ns was generated in order to accomplish this goal. The test consisted of a sequence of cycles that included thrust generation, heating without firing and system health checks. The manoeuvre was split in two parts, with a cooling period in between.

Telemetry data of a firing block:

The results of the overall functional thrust mode test are as follows:

- Water Tanks initial condition: 350g of water on each tank at a pressure of 3.4 atm

- Water consumed: 167.0 g

- Total Impulse: 240 – 260 Ns

- Thrust: 15 – 17 mN

- Test duration: 11h 25m (including cool down period)

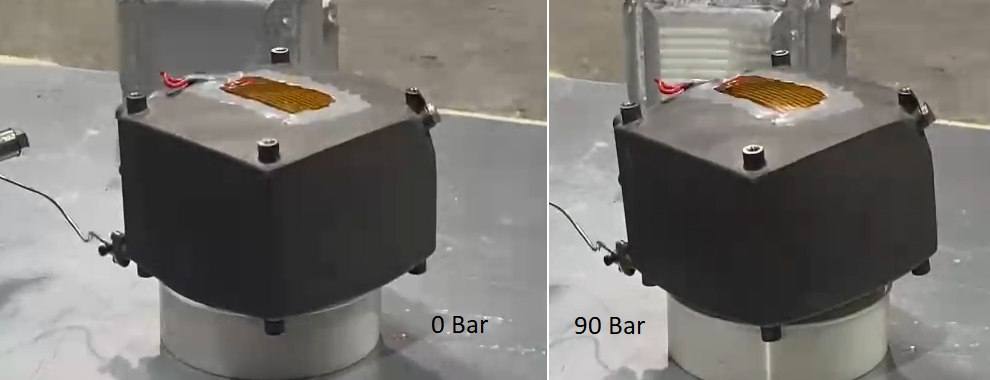

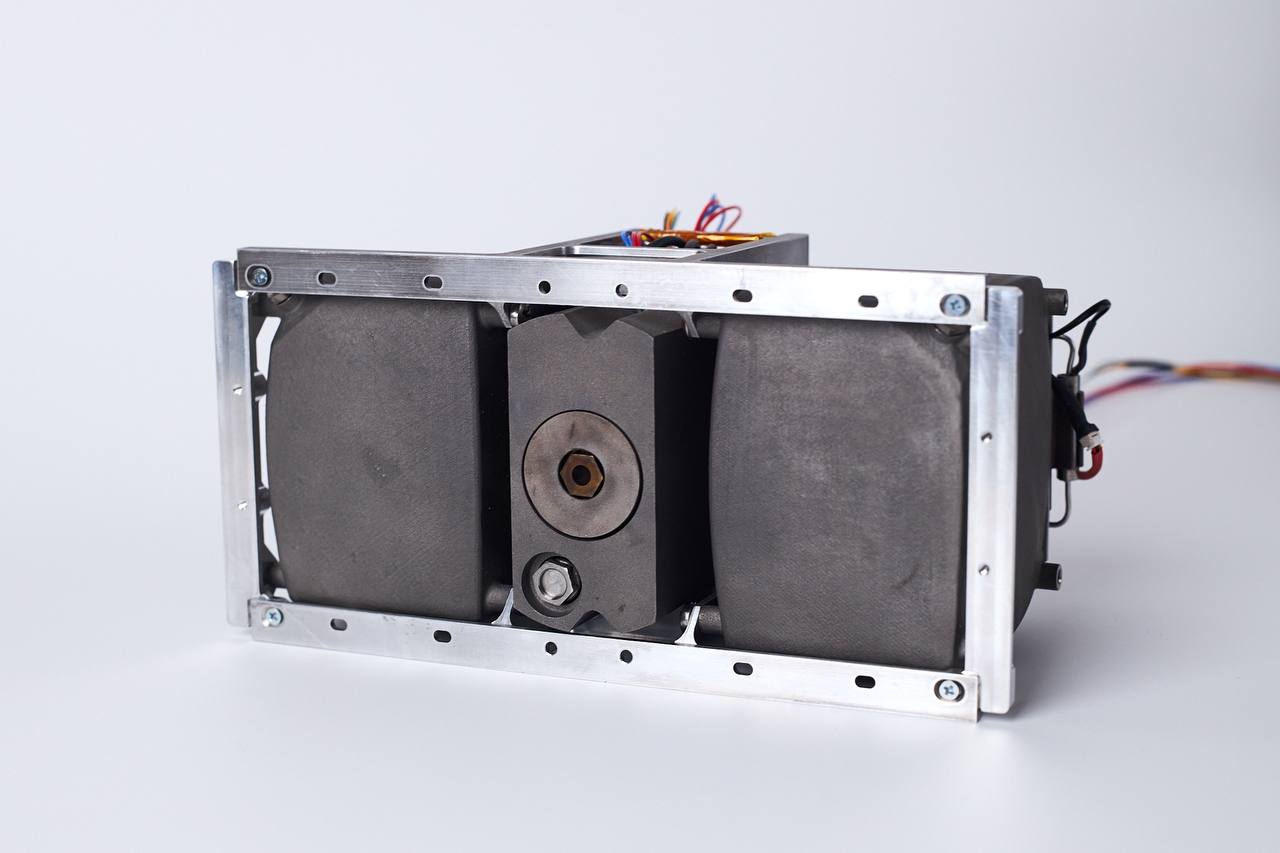

Vibration dynamic test

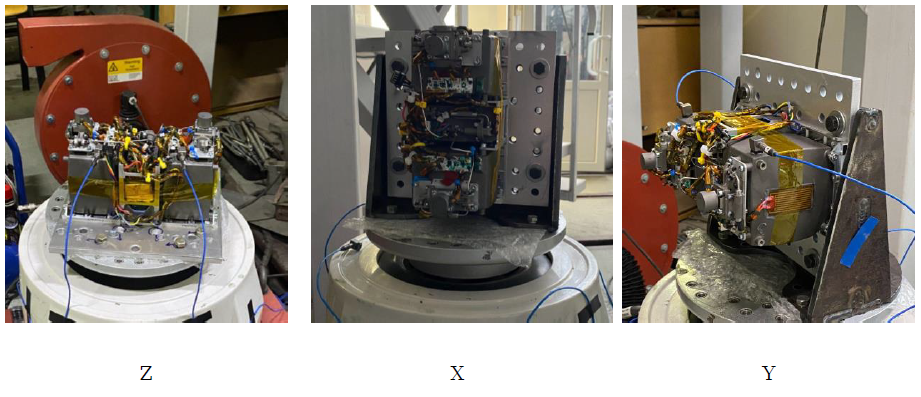

During the vibration dynamic test, engineers simulate operational conditions to ensure all components meet quality standards.

The vibration stand main specifications were the following:

Parameter | Value |

|---|---|

Stand | ETS_L620M.std |

Maximum payload weight [kg] | 300.0 |

Reduced mass of the moving system [kg] | 6.0 |

Operating frequency range [Hz] | 3.00 – 3500.00 |

Buoyancy force [N] | 6000.00 |

Maximum speed [m/s] | 1.80 |

Maximum movement [mm] | 25.00 |

Maximum acceleration [m/s2] | 980.00 |

Thruster mounting for vibrations testing along X,Y,Z:

During and after vibration dynamic testing, all thruster parameters remained within normal limits and met specifications.

Thermal vacuum test

The main goal of the thermal vacuum test is to check that the thruster performs and survives extreme temperatures encountered in space. Additionally, the test reveals any hidden issues early, reducing the chance of problems during the first hours of flight.

Engineers successfully completed all functional checks at the different dwell temperatures. The total mass loss during Thermal Vacuum was 0.7g, or 0.059 %, which confirms that the integrity of the thruster is maintained.

Leak rate

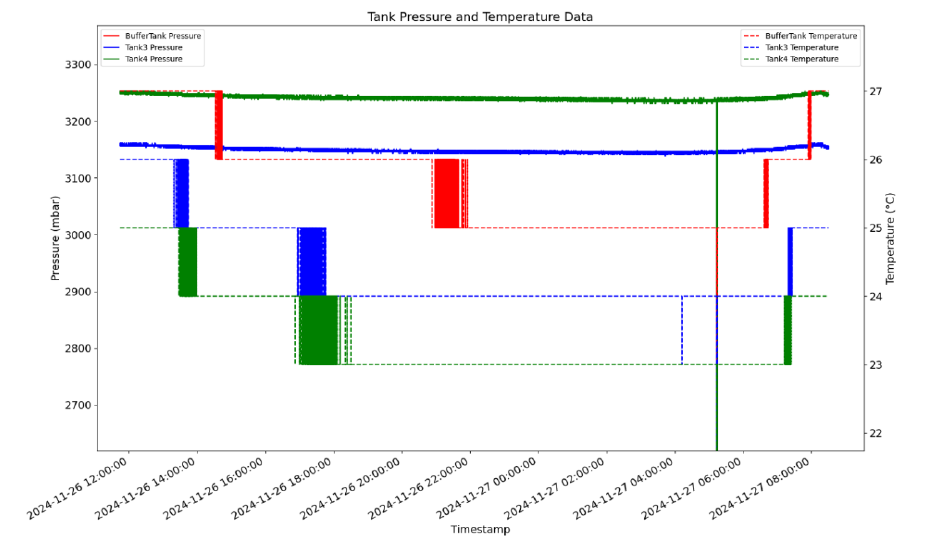

After the thermal vacuum test, engineers measured the leak rate. The thruster was fuelled and left for 20 hours in vacuum conditions while monitoring pressure and temperature values. Engineers detected no leaks during this 20-hour period.

Thruster telemetry during leak rate test:

Conclusion

SteamJet Thruster One has successfully completed all testing required for the Artemis II mission. Functional, vibration, thermal vacuum, and leak rate tests confirmed that the thruster performs reliably in all operational modes, maintains its integrity under extreme conditions, and meets mission requirements. With verified performance and no detected leaks, the thruster is fully flight-ready to perform the critical orbital correction for the K-Rad Cube satellite.

About SteamJet Space Systems

SteamJet Space Systems is a leading UK-based provider of high-performance satellite propulsion solutions. We specialize in water-based thrusters designed specifically for CubeSats and Small Satellites (SmallSats), with a strong focus on water-based thruster safety.

By pioneering the use of green propellants and intelligent thermal engineering, SteamJet enables complex LEO (Low Earth Orbit) maneuvers — including orbital maintenance, collision avoidance, and de-orbiting — without the risks of toxic hydrazine or high-pressure cold gas systems. This approach advances green propulsion for space missions.

Steamjet Propulsion Technology

Our modular systems are engineered for seamless integration and maximum safety compliance:

Steam TunaCan Thruster: A compact, high-efficiency solution for 1U-3U CubeSats.

Steam Thruster One: Scalable propulsion for larger SmallSat constellations.

Discover how SteamJet’s sustainable space propulsion innovations are providing the safety and reliability required for the next generation of crewed and robotic missions. Contact our engineering team for technical specifications and ICDs.