As the space industry shifts toward more compact and agile platforms, selecting the right small satellite propulsion system has become a critical mission-design decision. Among the various technologies available, cold gas propulsion for small satellites remains one of the most reliable and widely adopted solutions due to its inherent simplicity and safety. By utilizing the controlled expansion of a pressurized gas to generate thrust, these systems offer a low-complexity alternative to more power-intensive electric propulsion, making them an ideal choice for the growing CubeSat and SmallSat markets.

Propulsion is essential for today’s small satellite operations. They enable:

- Collision avoidance

- Constellation management

- Orbital maneuvers

- Deorbiting

- Station keeping

- Attitude control

There are various propulsion systems available for small satellites. Cold gas propulsion systems are one of them. And it is one of the simplest and most reliable solutions.

What Is Cold Gas Propulsion?

Cold gas propulsion generates thrust without heating the propellant. It relies on the expansion of pressurized gas.

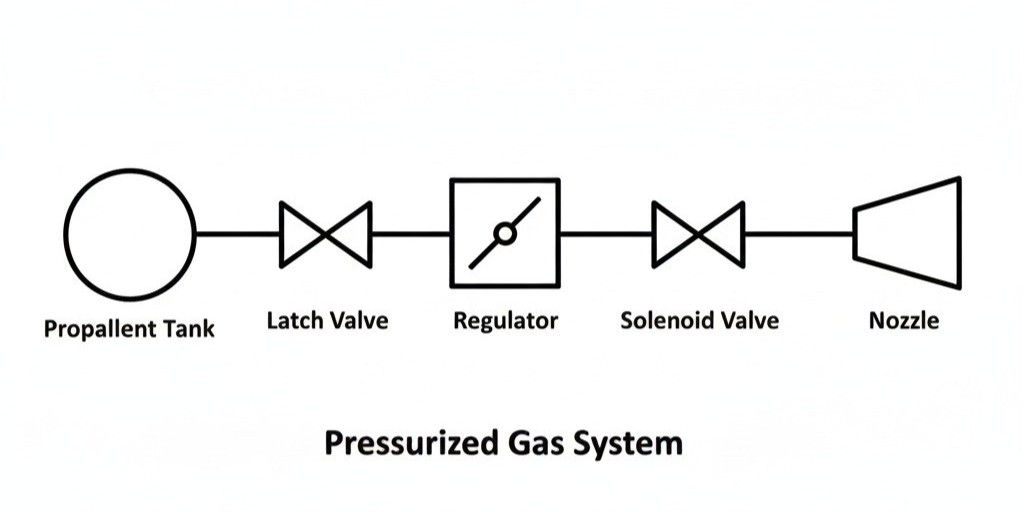

The system consists of:

- Propellant tank (high-pressure storage)

- Filter

- Valve system

- Nozzle

The propellant is stored under high pressure. It flows through the valve into the nozzle. Thrust is produced when the gas expands. The thrust generated is proportional to the pressure inside the tank.

Since there is no heater, the system doesn’t add thermal energy to the working fluid. Instead, it converts stored pressure energy into kinetic energy at the nozzle exit.

System Layout

Basic construction includes a tank, solenoid valve, and nozzle.

The pressure is reduced before the propellant reaches the thruster, allowing controlled and repeatable pulses.

Cold Gas vs. Electrothermal Propulsion

The primary difference between cold gas and electrothermal propulsion lies in the heater.

An electrothermal propulsion system includes:

- Heat exchanger

- Electric heater

In this type of system, the propellant (for example, water) is heated before expansion. Increasing temperature increases exhaust velocity and improves specific impulse.

When the heater and heat exchanger are removed, the system effectively becomes a cold gas thruster.

Performance Trade-Off

Cold gas systems do not add thermal energy. That is why their performance is typically 2–3 times lower compared to electrothermal systems.

However, there are certain benefits to eliminating the heater:

- Lower electrical power demand

- Reduced component count

- Higher overall reliability

- Simpler integration

In some missions, this simplicity is more valuable than peak efficiency.

Propellants Used in Cold Gas Systems

Cold gas propulsion requires propellants that can operate without additional heating.

Compressed gases:

- Nitrogen (N₂)

- Hydrogen (H₂)

- Argon (Ar)

- Helium (He)

Liquids stored at saturation conditions:

- Nitrous oxide (N₂O)

- Propane

- Ethane

- Carbon dioxide (CO₂)

Water is not suitable for cold gas mode. Without heating, it evaporates too slowly to generate meaningful thrust. That is why water-based propulsion systems operate in electrothermal mode.

Cold Gas Propulsion Limitations

The system is simple, but it has several important drawbacks:

- Lower Specific Impulse

Compared to electrothermal or electric propulsion systems, cold gas engines deliver significantly lower efficiency. - High-Pressure Storage Requirements

The system uses high-pressure tanks, which require rigorous leak testing and safety validation. - System Complexity in Gas Handling

While the thrust generation principle is simple, the storage and regulation of high-pressure gas involves regulators, valves, sensors, and safety components that must operate reliably in space.

Cold gas propulsion represents one of the most mature and reliable propulsion technologies available for small satellites. By relying solely on stored pressure energy, it eliminates the need for heaters and complex thermal subsystems.

While its specific impulse is lower than electrothermal alternatives, its robustness, simplicity, and operational predictability ensure that cold gas propulsion continues to play an important role. As noted in the NASA State-of-the-Art for Small Satellite Propulsion Systems, these systems remain a baseline for SmallSat missions due to their high reliability and low integration risk.

Comparison: Cold Gas vs. Electrothermal Propulsion

Feature | Cold Gas Propulsion | Electrothermal Propulsion |

|---|---|---|

Heating Mechanism | No heater; relies on expansion of pressurized gas. | Includes an electric heater and heat exchanger. |

Performance (Specific Impulse) | Typically 2–3 times lower efficiency. | Higher exhaust velocity and improved specific impulse. |

Power Consumption | Lower electrical power demand. | Higher power required to operate the heating system. |

System Complexity | Simpler with fewer components (no thermal subsystems). | More complex due to added heaters and heat exchangers. |

Reliability | Higher overall reliability due to simplicity. | Slightly reduced due to more components and thermal stress. |

Common Propellants | Nitrogen, Hydrogen, Argon, Helium, CO₂. | Water (requires heating to evaporate and generate thrust). |

The primary difference between cold gas and electrothermal propulsion is that cold gas systems lack a heater, making them simpler and more reliable, while electrothermal systems offer 2-3 times higher performance by heating the propellant.

About SteamJet Space Systems

SteamJet Space Systems is a leading UK-based provider of high-performance satellite propulsion solutions. We specialise in water-based thrusters designed specifically for CubeSats and Small Satellites (SmallSats), with a strong focus on water-based thruster safety.

By pioneering the use of green propellants and intelligent thermal engineering, SteamJet enables complex LEO (Low Earth Orbit) manoeuvres — including orbital maintenance, collision avoidance, and de-orbiting — without the risks associated with toxic hydrazine or high-pressure cold gas systems, advancing green propulsion for space missions.

Steamjet Propulsion Technology

Our modular systems are engineered for seamless integration and maximum safety compliance:

- Steam TunaCan Thruster: A compact, high-efficiency solution for 1U-3U CubeSats.

- Steam Thruster One: Scalable propulsion for larger SmallSat constellations.

Discover how SteamJet’s sustainable space propulsion innovations are providing the safety and reliability required for the next generation of crewed and robotic missions. Contact our engineering team (link) for technical specifications and ICDs.