Spacecraft Propulsion Safety for a Crewed Artemis II Mission

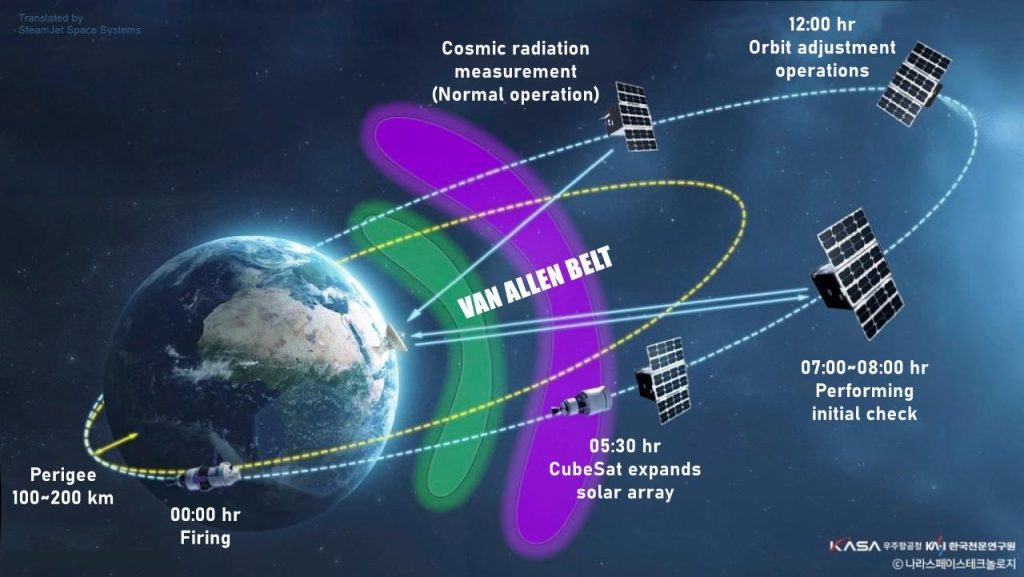

Tank burst safety is a critical requirement for crewed space missions. For Artemis II mission, SteamJet Space Systems is preparing to demonstrate spacecraft propulsion capabilities by performing an in-orbit correction for South Korea’s K-RadCube satellite. As a result, this manoeuvre is designed to prevent premature atmospheric re-entry and relies on a simple principle: using water as the propellant.

Artemis II Mission Safety Requirements

Artemis II is a manned mission; therefore, safety and reliability are imperative. Every element of the propulsion system must withstand conditions well beyond nominal operation. In particular, the pressurised, space-grade propellant tank must safely tolerate extreme internal pressures. This capability is a critical factor for CubeSat safety and crewed mission compatibility.

For this reason, the SteamJet team performed fuel tank burst pressure testing last year to confirm that the pressurized tank meets the Design Burst Pressure requirement defined in ANSI/AIAA S-080A-2018, Section 10.4.10, as part of CubeSat mission qualification.

Why Fuel Tank Burst Testing Is Required

A fuel tank must demonstrate compliance with a burst factor (BF) of 2.5. In this case, the maximum Design Pressure (MDP) is 5.67 bar. Therefore, the required design burst pressure (DBP) is calculated as 2.5 times MDP, which results in 14.18 bar.

Design Burst Pressure = BF x ECF x MDP = 2.5 x 1.0 x 5.67 = 14.18 bar

Test Environmental Conditions

The test was conducted near ambient temperature, approximately 20°C. As a result, the environmental correction factor (ECF) remained 1.0.

During the test, pressure increased progressively at a controlled rate. This approach prevented transient load spikes or dynamic effects, thereby ensuring representative water-based thruster safety conditions.

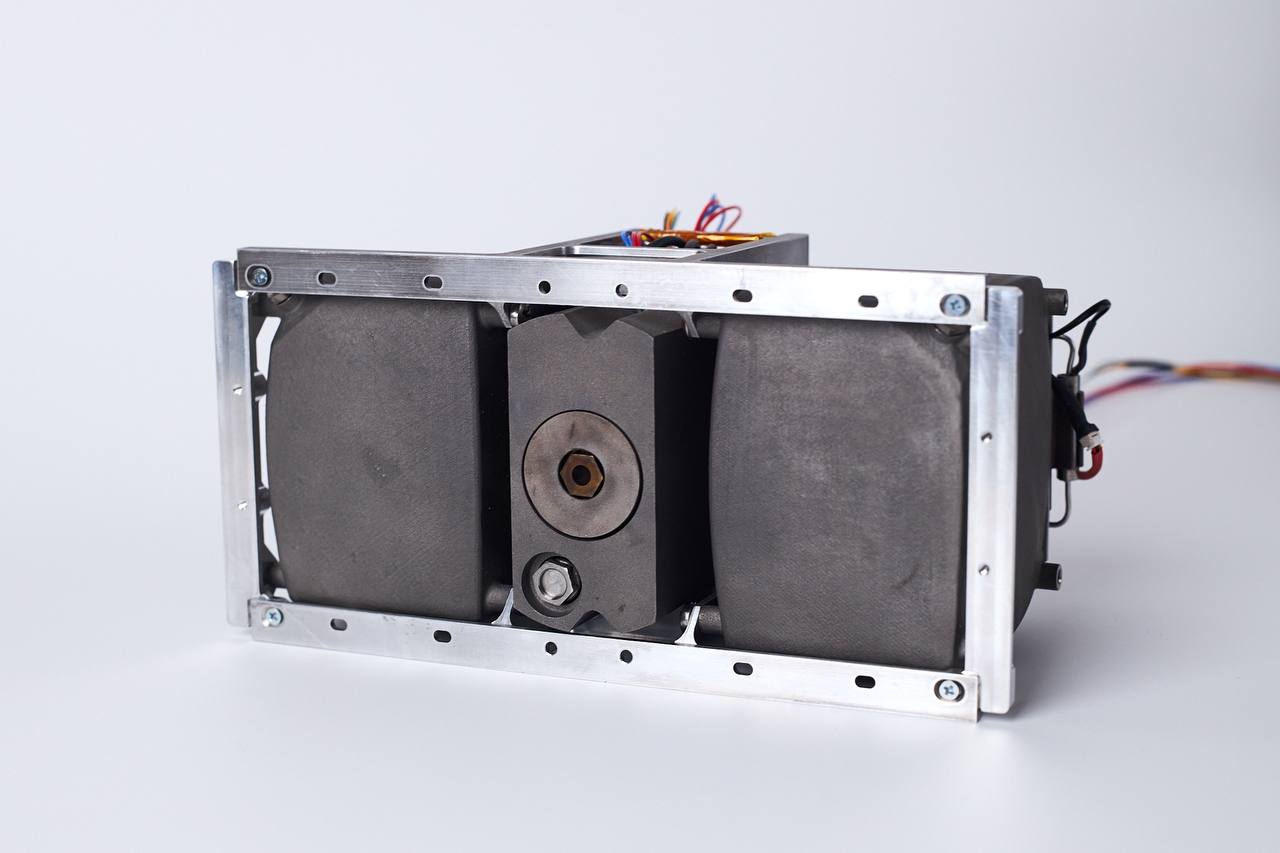

Tank Burst Test Setup

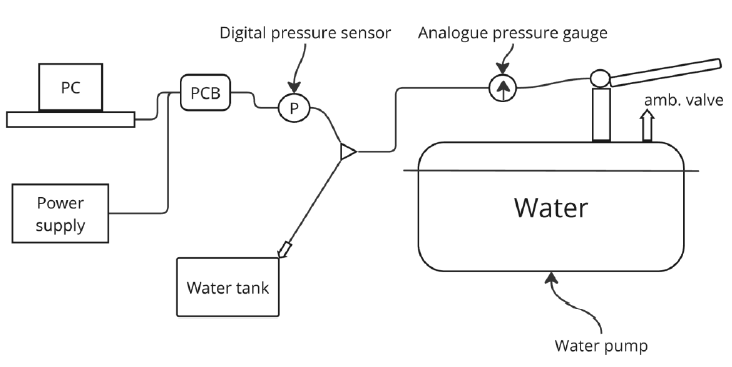

The team positioned the pressurised tank inside a safe container to protect against shrapnel or fluid jetting in the event of rupture. Next, they connected it to a water pump designed to exceed the required burst pressure through pressure-rated fittings and hoses. Pressure gauges and sensors continuously monitored the internal pressure. In addition, temperature sensors monitored ambient conditions. The team placed them near the tank, which is consistent with space-grade propellant tank testing practices.

Instrumentation and Monitoring

The team checked the system for leaks and functionality in advance and then filled it with water. After that, all instrumentation connected to a data acquisition system for continuous monitoring and recording throughout the test.

Because the electronic pressure sensor was limited to 30 bar, the team monitored higher pressure levels using an analogue gauge. A schematic of the test setup is shown below.

Tank Burst Test Procedure

The test began with a leak check at 5.67 bar to confirm the system was secure. Pressure was then gradually increased until it reached the calculated Design Burst Pressure of 14.18 bar. At this stage, the team held the pressure for about two minutes to verify tank integrity in line with CubeSat safety requirements.

Because the digital sensor could only measure up to 30 bar, it was removed, and the system was depressurised before continuing with the analogue gauge. Afterwards, pressure increased steadily until the tank burst. The team recorded the exact burst pressure, along with time, temperature, and the location and type of failure. Throughout the test, the team continuously monitored the system and logged all data from a safe distance.

Failure Location and Structural Behaviour

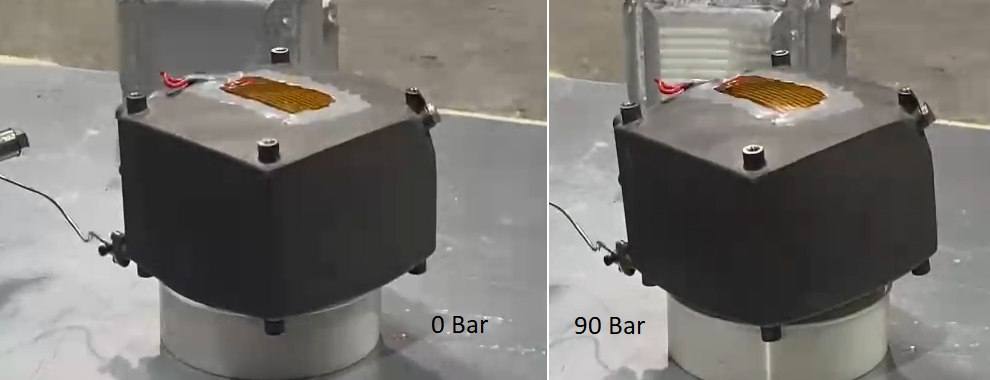

The tank was first pressurised up to 30 bar without rupture. After depressurisation and removal of the digital pressure sensors, the team re-pressurised the tank in a continuous event. The tank burst at 90 bar. Notably, this observed burst pressure far exceeds the required design burst pressure of 14.18 bar.

As a result, the test confirmed that the fuel tank is capable of exceeding the minimum requirement with a substantial margin, supporting CubeSat mission qualification and crewed mission safety.

Failure Mode and Stress Concentration

The failure happened along the edge of the tank, where stress concentrations are highest. It is consistent with the results of stress analysis. The tank edges and the centers of the smaller faces are the key areas of stress concentration.

Parameter | Required (DBP) | Actual Result | Safety Margin |

|---|---|---|---|

Pressure (bar) | 14.18 bar | 90 bar | ~ 6.3x |

Standard | ANSI/AIAA S-080A-2018 | Compliant | – |

Temperature | 20°C (Ambient) | 20°C | – |

In conclusion, the design burst pressure of 14.18 was successfully verified. The final burst pressure recorded was 90 bar. Therefore, the results demonstrate an excellent safety margin of the tank design for space-grade propellant tanks used in green propulsion systems.

About SteamJet Space Systems

SteamJet Space Systems is a leading UK-based provider of high-performance satellite propulsion solutions. We specialize in water-based thrusters designed specifically for CubeSats and Small Satellites (SmallSats), with a strong focus on water-based thruster safety.

By pioneering the use of green propellants and intelligent thermal engineering, SteamJet enables complex LEO (Low Earth Orbit) maneuvers — including orbital maintenance, collision avoidance, and de-orbiting — without the risks associated with toxic hydrazine or high-pressure cold gas systems, advancing green propulsion for space missions.

SteamJet Propulsion Technology

Our modular systems are engineered for seamless integration and maximum safety compliance:

- Steam TunaCan Thruster: A compact, high-efficiency solution for 1U-3U CubeSats.

- Steam Thruster One: Scalable propulsion for larger SmallSat constellations.

Discover how SteamJet’s sustainable space propulsion innovations are providing the safety and reliability required for the next generation of crewed and robotic missions. Contact our engineering team for technical specifications and ICDs.