Today, the space industry is developing rapidly, which presents additional challenges to academic programs. It is no longer sufficient to teach theory to students who train for careers in aerospace, satellite operations, and mission control. They need hands-on, practical experience with real CubeSat propulsion systems. However, many university programs still offer simulation-based learning in a classroom, which leads to a critical gap between education and actual spaceflight experience.

Aerospace Education Gap

Many universities worldwide provide excellent fundamental knowledge in orbital mechanics, control systems, satellite design, and mission planning. Students run simulations, model satellite behaviors, and plan maneuvers. But many recent graduates find themselves not fully prepared for real-world in-orbit operations.

This gap between theory and practice is particularly noticeable in areas like CubeSat propulsion technology, trajectory optimization, and satellite navigation. Lack of operational experience may lead to expensive mistakes. Thus, it is clear that students need earlier access to real spacecraft systems.

Why Real Space Experience Matters

There is a big difference between simulation and operating a thruster in orbit. When students install thrusters, test them, and eventually operate them in flight, they gain invaluable technical and problem-solving skills, as well as build professional confidence. These kinds of skills and approaches are impossible to teach only through software tools.

Real-life experience with propulsion systems allows students to practice mission-critical roles:

- Planning and executing orbital maneuvers

- Monitoring system performance

- Diagnosing and responding to challenges in real-time

Steam-Based Thrusters: Practical Training for Students

Steam-based propulsion systems are a perfect fit for educational programs. Our technology uses safe, non-toxic water propulsion and operates at low pressure. Hence, it is ideal for student programs where simplicity, safety, and accessibility matter most.

- No hazardous materials – water is safe to handle and doesn’t require specialized certification

- Low-pressure operation – reduces lab and integration risks

- CubeSat-compatible – designed for small satellite missions

- Simple electronics – easy to integrate and operate with limited resources

Real Missions for Future Engineers

By working with spacecraft propulsion systems students receive experience with a full mission lifecycle, and they learn to make decisions that have real consequences. This kind of training builds precisely the expertise that the current aerospace industry demands.

Whether your university is launching its first CubeSat or expanding a satellite program, SteamJet offers a tangible path to professional-level experience. Our systems give student teams the chance to build, test, and fly real space propulsion — all while staying safe and budget-friendly.

Interested in integrating space propulsion training into your university’s program? We’re here to help. Contact SteamJet to learn how our technology can support your student satellite missions and help bridge the gap between theoretical education and practical, real-world spacecraft operations.

We offer a special program and pricing for universities and academic institutions — making it easier to bring real propulsion systems to your students.

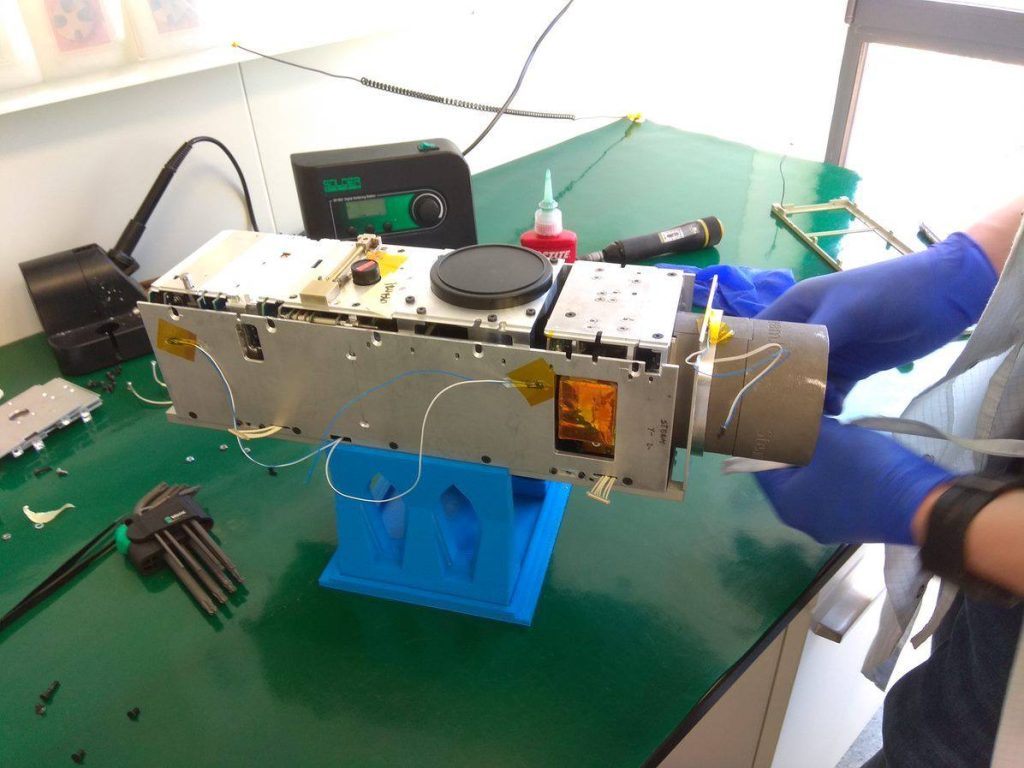

Detailed technical specifications, test data, and CAD models for our new space engines are available on our website. Steam TunaCan Thruster and Steam Thruster One. Discover how SteamJet innovations are shaping the future of sustainable satellite propulsion.

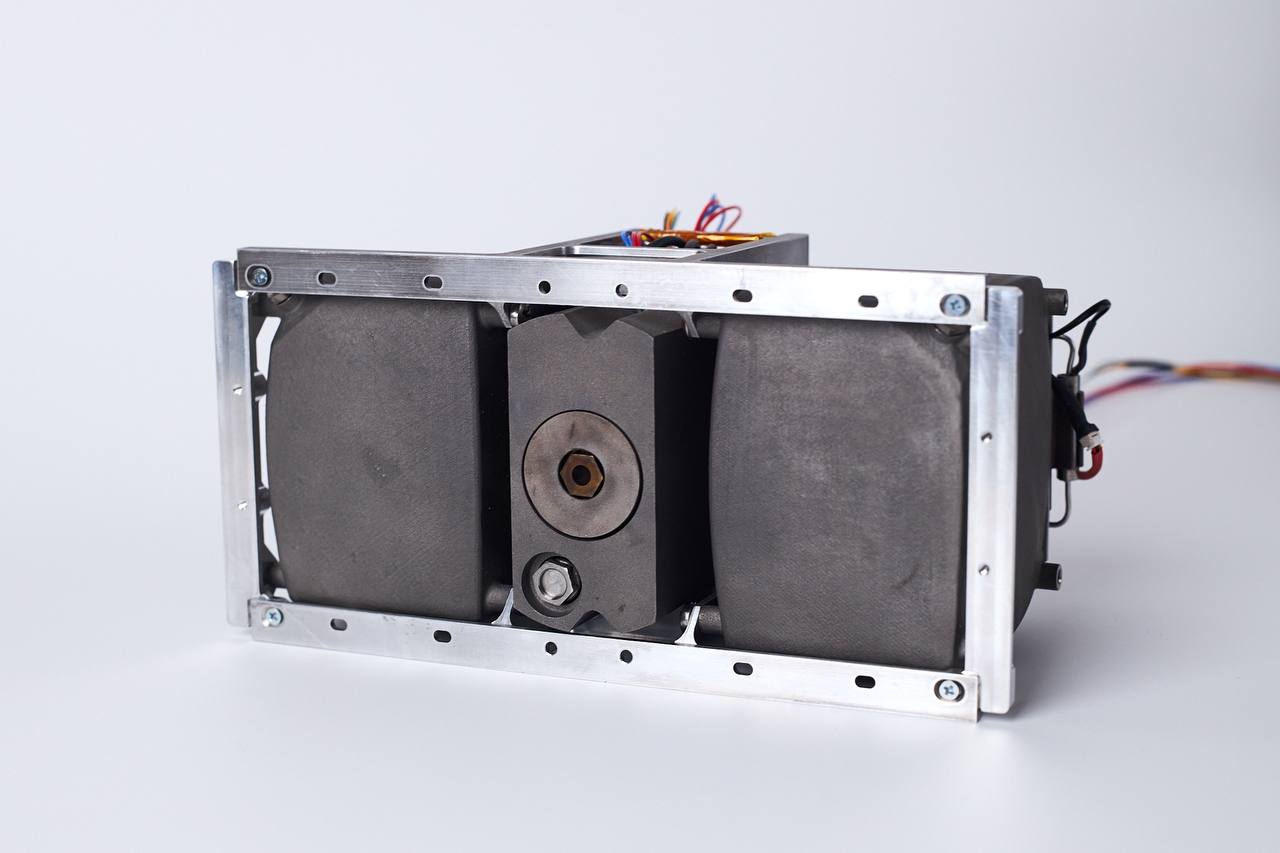

Satellite thruster systems have to be tested to ensure their reliability. Thus, it is crucial to simulate operational conditions during the development process. There are multiple external factors that affect the thruster at the launch, which are outlined in the launch vehicle manual. Potential issues involve vibrations, acceleration and the abrupt forces on both first and second stages. A vibrodynamic test bench simulates these vibrations, reproducing the unique characteristics of the launch vehicle.

Satellite thruster systems have to be tested to ensure their reliability. Thus, it is crucial to simulate operational conditions during the development process. There are multiple external factors that affect the thruster at the launch, which are outlined in the launch vehicle manual. Potential issues involve vibrations, acceleration and the abrupt forces on both first and second stages. A vibrodynamic test bench simulates these vibrations, reproducing the unique characteristics of the launch vehicle.